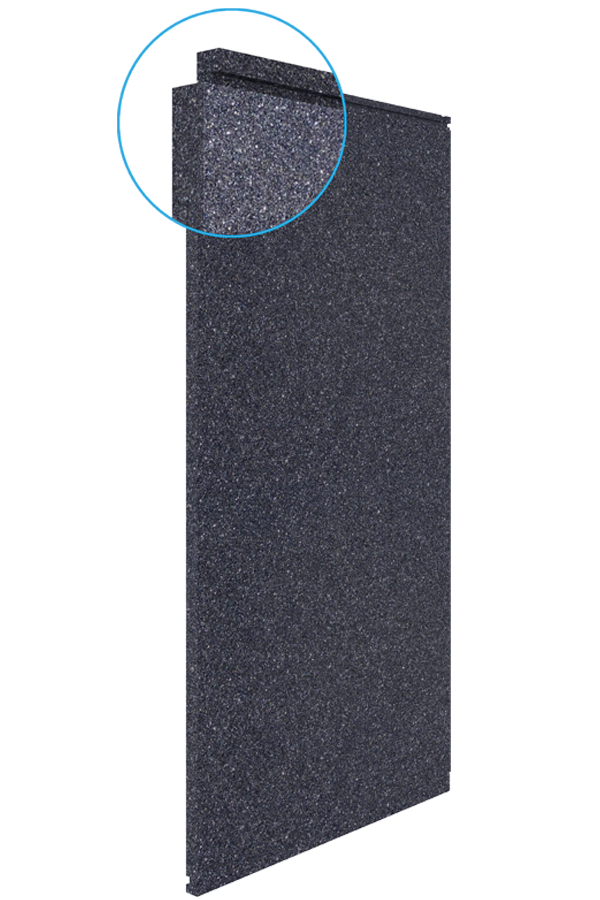

NEOTHERM™ | T1 – T 2 – T 3

Attached files

Open or select files to share.

Description

RECOMMENDED USE

Install Neotherm™ rigid insulation board loose laid, fully adhered or mechanically fastened for a continuous thermal envelope. It is used in the design of several high performance roofing systems and walls of commercial, industrial and institutional building.

APPLICATIONS

Flat roofs, cathedral roofs, metal roofs, exterior and interior walls, foundation walls, basement walls, backfill insulation and other insulation projects.

CERTIFICATION

Warnock Hersey has certified the expanded polystyrene contained in rigid insulation boards in accordance with the CAN/ULC-S701-11 standard. The expanded polystyrene from Millenium is listed in the CCMC Registry of ProductEvaluation under CCMC 13276-L [type 1], CCMC 13271-L[type2] and CCMC 13277-L [type3].

FEATURES AND BENEFITS

- R-value which remains permanent with time;

- Excellent moisture resistance within the walls;

- Non vapour barrier – Enclosed rigid plastic cells that allows water vapour diffusion while maintaining the insulating value;

- Versatile, lightweight, easy to transport and install;

- 100% recyclable material;

- Meets current building code requirements;

- Meets CAN/ULC-S701-11 standard.

ENVIRONMENTAL DATA

Expanded polystyrene included in rigid insulation boards are composed of 98% air and 2% plastic material. They are manufactured without HCFC or HFC gases and without HBCD flame retardant.The Millenium products can contribute to LEED credits for Optimizing Energy Performance, Recycled Content, RegionalMaterials, Low-Emitting Materials [Adhesives and Sealants], Construction Waste Management and IAQ Management Plan for the Pre-Occupancy Phase.Please send us your LEED Material Declaration Formatinfo@millenium.plus.

LIMITATIONS

Expanded polystyrene is combustible. Even if expanded polystyrene contains a flame retardant, limit use of open flame or ignition sources near product. A protective barrier or thermal barrier is required as specified in the appropriate building code. Expanded polystyrene may be affected by some oil based solvents. An excessive heat accumulation can deform products made with Neopor®.

EXEMPTION OF LIABILITY

The information herein is based on the present state of our best scientific and practical knowledge. The user is responsible for checking the suitability of products for their intended use. Millenium technical data sheets are updated on a regular basis; it is the user’s responsibility to obtain and to confirm the most recent version. Information contained in this data sheet may change without notice.

STORAGE

Store boards in a dry location, protected from the outside elements, ultraviolet rays, open flames or other sources of ignition. Stack boards on pallets of minimum 100 mm [4”] above the ground.To limit the color loss from UV exposure, cover the installed boards with an exterior cladding protecting from ultraviolet rays. Pay special attention to the storage of the Neotherm™ panels. They are made with Neopor®. Cover the unwrapped Neotherm™ panels or if packaging has been damaged with an opaque white tarp. An excessive heat accumulation can deform products made with Neopor®. Do not store the Neotherm™ panels near any reflectives surfaces [ex: glass, metal]. A heat concentration from reflected sunlight can deform products made with Neopor®.

INSTALLATION

Boards must be dry and in good condition before installation. To limit the color loss from UV exposure, cover the installed boards with an exterior cladding protecting from ultraviolet rays. Avoid the prolonged exposure to sunlight of the Neotherm™grey/black surface. Avoid the concentration of sunlight rays from radiation. Cover as soon as possible on hot days and/or during non-windy conditions. An excessive heat accumulation can deform products made with Neopor®. NEOPOR® Registred Trademark of BASF.

Technical informations

THERMAL VALUE

| Dimensions | Thickness | Type 1 | Type 2 | Type 3 | ||

|---|---|---|---|---|---|---|

| 610 mm x 2438 mm | [24” x 96”] | 25 mm | [1”] | R4.7 | R4.75 | R4.8 |

| 1219 mm x 2438 mm | [48” x 96”] | 38 mm | [1-½”] | R7.1 | R7.1 | R7.2 |

| Other dimensions and thickness available upon request. Square joints by default. | 51 mm | [2”] | R9.4 | R9.5 | R9.6 | |

| Other dimensions and thickness available upon request. Square joints by default. | 64 mm | [2-½”] | R11.8 | R11.9 | R12 | |

| Other dimensions and thickness available upon request. Square joints by default. | 76 mm | [3”] | R14.1 | R14.3 | R14.4 |

Ship lap joints available on two sides for 25 mm [1”] thick panels. For panels with a minimum thickness of 38 mm [1-½”], ship lap joints available on two or four sides or EZ clip system available on two or four sides. To obtain the RSI valuedivide the R value by 5.678

TECHNICAL DATA

| Physical properties | |||

| Neotherm™ | Type 1 | Type 2 | Type 3 |

| Thermal Resistance Min | RSI 0,85 | RSI 0,84 | RSI 0,85 |

| [ASTM C518] Épaisseur de 25 mm [1”] | [R4.7] | [R4.75] | [R4.8] |

| MVTR Max | 300 ng/Pa.s.m² | 200 ng/Pa.s.m² | 130 ng/Pa.s.m² |

| (ASTM E96) | [5,24 US Perms] | [3,5 US Perms] | [2,27 US Perms] |

| Compressive Strength Min | 70 kPa | 110 kPa | 140 kPa |

| [ASTM D1621] 10 % de déformation | [10 PSI] | [16 PSI] | [20 PSI] |

| Flexural Strength Min | 170 kPa | 240 kPa | 300 kPa |

| [ASTM C203] | [25 PSI] | [35 PSI] | [44 PSI] |

| Water Absorption Max | |||

| [ASTM D2842] Volume | 6 % | 4 % | 2 % |

| Dimensional Stability Max | |||

| [ASTM D2126] Variation linéaire | 1,5 % | 1,5 % | 1,5 % |

| Limiting Oxygen Index Min | |||

| [ASTM D2863] | 24 % | 24 % | 24 % |

| Density Min | 16 Kg/m³ | 20 Kg/m³ | 25 Kg/m³ |

| [ASTM C303] | [1,00 lbs/pi³] | [1,25 lbs/pi³] | [1,5 lbs/pi³] |

| Flame Spread Rating | |||

| [CAN/ULC S102.2] | 240 | 240 | 240 |